Diode Lasers for Semiconductor Process Control

Using diode lasers for semiconductor inspection and process control

- Critical Dimensions

- Inspection

- Ellipsometry

- Microlithography

- Thin Film Analysis

- Lithography Optics Inspection

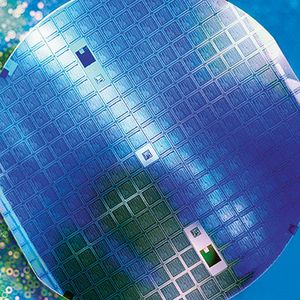

The semiconductor industry deeply relies on sophisticated processing and quality analysis tools. Optimal inspection is achieved by non-tactile means, where the sample is not brought into contact with hazardous materials, the environmental gas or vacuum is not polluted and handling is very flexible. Amongst these methods, laser based technologies are appreciated for their wide range of opportunities, superior spatial resolution and extreme sensitivity. And amongst all lasers, compact diode lasers with optimized wavelength, polarization and beam quality are currently the first choice for many advanced optical inspection techniques due to long life time and clean room compatibility.

TOPTICA's fields of expertise include:

- Thin film analysis is accomplished by using polarized light for ellipsometry.

- Flexible micro-lithography makes use of unique and easy to operate single-mode diode lasers in the blue and UV spectral range.

- Gases like oxygen or hydrogen can be detected remotely in sealed environments by using IR diode lasers, which are rapidly tuned over characteristic molecular absorption frequencies.

- Particles can be detected by analyzing the scattered light from a bright diode laser beam.

- Masks in wafer steppers can be aligned interferometrically with ultimate precision by using single-mode diode lasers.

- Expensive lithography optics can be inspected by using highly coherent UV CW diode lasers, etc. etc.